Where Time Is Still Made by Hand: A Visit to Laurent Ferrier

Watchmakers have always been tied to their creations in one way or another, whether it is in their name, their design, or their heritage. Names like Breguet still carry the weight that they did 200 years ago. Yet, in a world with millions watchmakers, producing more watches than ever before, it can feel like the name on the dial is dissociated from the craftsman. This is an era of industrial watchmaking. Amongst the huge manufactures producing millions of pieces per year, there is a small crowd of watchmakers who are determined to carry tradition forwards and maintain this unique personal relationship with their watches. Laurent Ferrier is one of them. Their interpretation of this special bond is simple: a single watchmaker is responsible for the watch’s whole journey in the manufacture. This means that when you buy a Laurent Ferrier watch, it has been hand-finished and assembled by a single craftsman. And that rule still stands when it comes back for servicing.

When I first met with the team at Laurent Ferrier at Watches & Wonders earlier this year, I was blown away by the beauty of their watches: they are undeniably gorgeous watches. However, it was discovering the processes behind the creation of the watches that has made them all the more alluring to me. How could I refuse when the opportunity arose to visit the manufacture? And that is how I found myself standing in a car park in a quiet industrial estate on the outskirts of Geneva in early September. From the outside, you would not be able to guess what went on inside such an unsuspecting building. Even the manufacture’s neighbours could not tell us where to find the front door…

It is probably a good time to give you a bit of context about Laurent Ferrier as a watchmaker, and as a brand. As with many big industry names, Laurent Ferrier is indeed the watchmaker who has given his name to a manufacture. However, unlike many of these big names, he is a figure of the present. Formerly a watchmaker and then department head at Patek-Philippe, Mr. Ferrier is a serious name: he is the man behind the Nautilus Chronograph and the Aquanaut, just to name a few of his pieces. If this isn’t impressive enough, Mr. Ferrier is also an extremely accomplished racing driving, even placing 3rd at Le Mans in 1979. To properly grasp LF’s timepieces, all you need to keep in mind is the connection with Patek and racing.

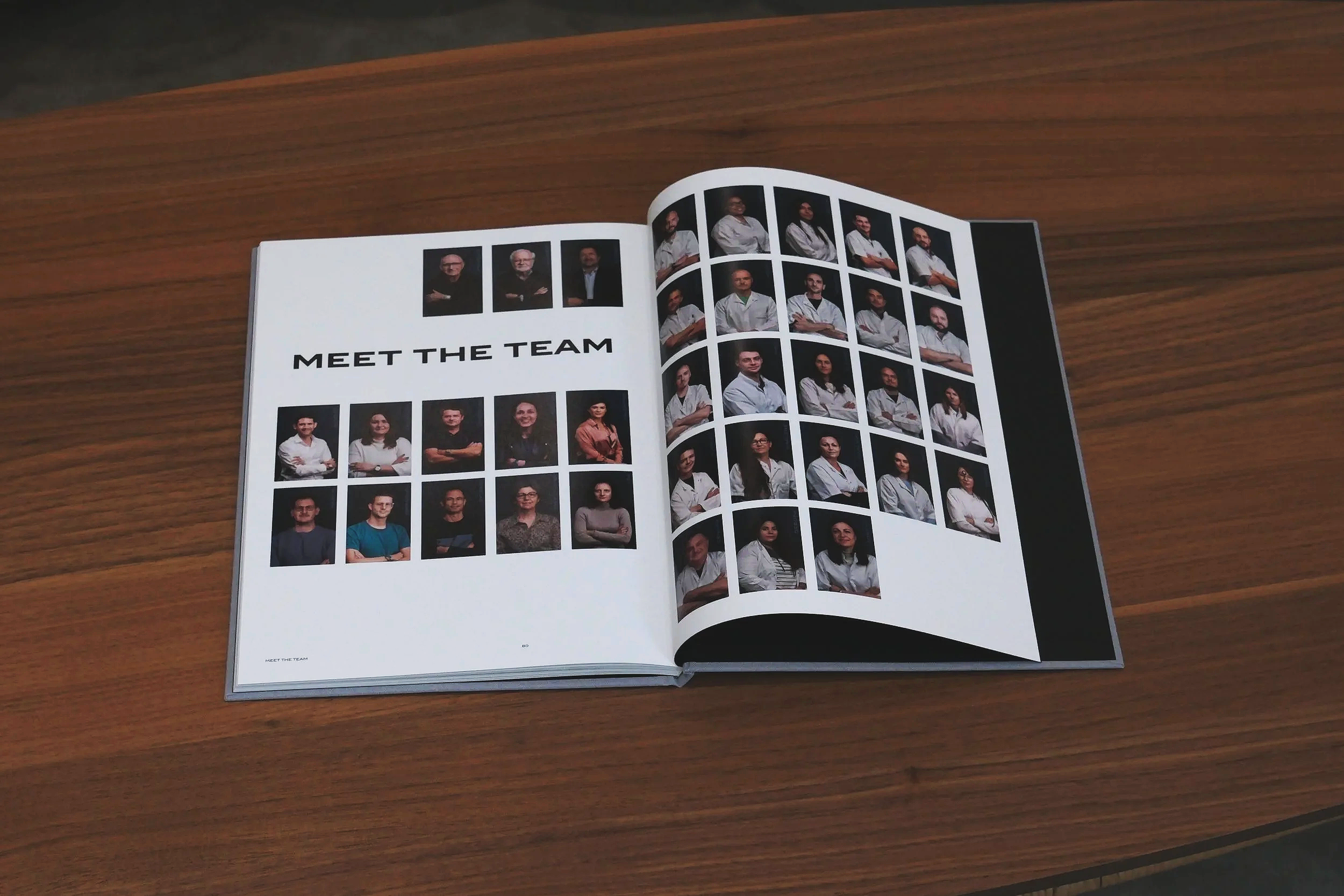

The brand itself is a tight-knit team of 38 people, who work tirelessly to produce around 500 simply magnificent watches per year: a far cry from the numbers of a brand like Cartier or Rolex. The modest size of its operations are completely disproportionate to their influence and reputation. In just 15 years of existence, Laurent Ferrier have won 5 GPHG awards, and look set to win another this year. It is hard to explain just how impressive this really is. However, I would note that this is also a completely unsurprising fact when their processes and holistic vision of watchmaking comes to your attention. If you make fabulous watches, then of course you’re going to win big.

Speaking of holistic watchmaking, Laurent Ferrier watches are a bit of a family affair. Mr. Ferrier’s son joined the team, bringing with him years of experience in the Roger Dubuis movement department. This partnership really reinforces the integrity and intimacy of the watches: they are the product of a powerful father and son effort. Concretely, this allows for a beautiful continuity of thought and purpose throughout the pocket-watch style movements and the rest of the watch: both sets of components complement each other perfectly. The dialogue and connection required to execute such a piece is remarkable: this is the human dimension of Laurent Ferrier’s watches that is so important. I will reiterate that this is what differentiates these watches from everything else on the market.

Now that we’ve some of why behind their watches, let’s talk about how Laurent Ferrier go about designing, manufacturing, and assembling them. I think it is important to note that Laurent Ferrier’s watches are not 100% in-house. The term has many meanings in the industry, ranging from designing a proprietary movement to completely designing and manufacturing the whole calibre. Indeed, Laurent Ferrier’s movements are designed completely in-house. However, due to the size of their operations, they just do not have the capacity to produce every component they need. Instead, they are ordered from a range of suppliers across Switzerland. And this is where our journey at the manufacture started in earnest: the quality control department. The components delivered to the manufacture are of the highest quality, however, Laurent Ferrier have an even more stringent internal control: their components need to be perfect both dimensionally and aesthetically, to ensure that the finial product is flawless. With over 200 individual components in each of their movements, the watchmakers and engineers in the quality control department have got their work cut out for them, even though they are aided by some very high-tech measuring devices.

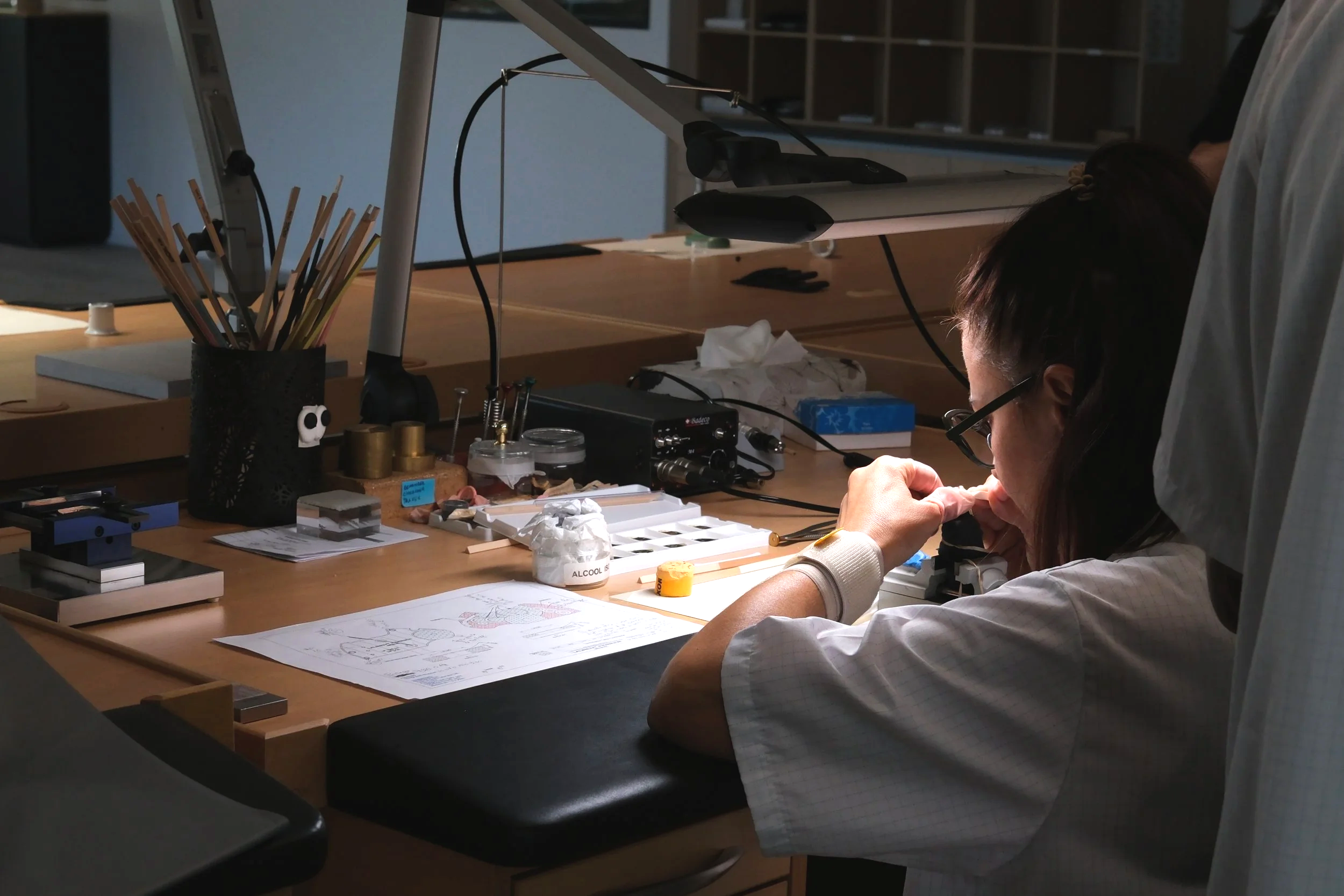

From the quality control department, they are then packed into individual ‘kits’ for the watchmakers to start the finishing process. This is arguably the longest step of a watch’s journey through the manufacture: each of the 200+ components in the movement is finished individually and by hand, by the watchmaker who will eventually assemble the final watch. Put like that it might seem rather simple, however, each individual component is finished using between 3-5 techniques. To successfully bevel and polish one of the movement’s bridges, the watchmaker employs diamond coated sandpaper of varying granularities, before moving onto the final polish using hand cut gentian or ebony sticks. I expected a watch manufacture to be a clean and pristine environment, and it was, expect for the small piles of wood shavings piling up at the watchmaker’s feet. On aggregate, the hand finishing takes up a serious chunk of time: this is where the relationship between craftsman and masterpiece really comes to life.

The process really speeds up from here. The watch is assembled twice by the watchmaker. The first is a dry run to ensure that all the components are correctly finished and fit properly. The second assembly is the final run through using the plethora of oils and lubricants necessary for the correct running of the watch. The watch is really on the home straight, going through stringent regulation, adjustment, and testing processes like many other watches.

Stepping foot in the Laurent Ferrier manufacture was so far removed from anything I had ever imagined. I was expecting to be met with an incredibly sterile high-performance environment that was cold, clinical, and pragmatic. Yet, I was struck with how human the whole manufacture felt. Indeed, the facilities were sterile and clinical, the watchmakers were incredibly pragmatic and clearly incredibly talented, but the atmosphere felt very intimate and dynamic, despite the prevailing silence in the ateliers. Visiting Laurent Ferrier’s manufacture has changed my perception of modern watchmaking. What I saw was not an impersonal factory floor, but a community of craftspeople working in unison, each carrying the weight of Ferrier’s monument-like ideals. In an age defined by scale and speed, this small Geneva workshop stands as a quiet reminder that excellence still depends on the human touch.